Why the Small Hole in a Safety Pin Is More Helpful Than You Realize

The Quiet Brilliance of the Safety Pin: A Small Hole with a Big Purpose

The safety pin may be one of the clearest examples of practical simplicity ever created. At first glance, it’s nothing more than a shaped piece of stiff wire, fitted with a spring and a clasp that keeps the sharp end safely tucked away. It’s a universal object, found in first-aid kits, sewing boxes, and laundry drawers, used for quick clothing fixes, securing bandages, or pinning race numbers. Yet its very familiarity makes its cleverness easy to overlook. Hidden in plain sight is a tiny detail that reveals just how thoughtfully this everyday tool was designed.

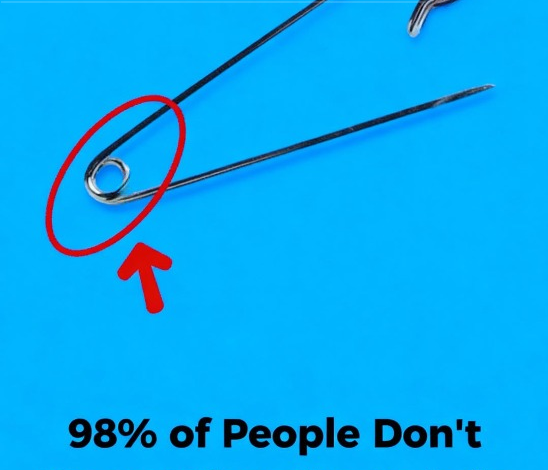

If you look closely at the end opposite the clasp, where the wire curves back on itself to form the spring, you’ll notice a very small, perfectly round hole punched through the metal loop. Most people assume this opening is meaningless, perhaps a leftover from manufacturing, a quirk of the bending process, or even a decorative detail. In truth, that hole is neither accidental nor decorative. It was intentionally added as a multifunctional feature rooted in traditional sewing practices, and knowing why it exists unlocks a remarkably efficient technique that has been used for generations.

This feature was created to solve one of the most irritating tasks in clothing repair and construction: feeding elastic, ribbon, or drawstrings through fabric casings.

A casing is the enclosed fabric tunnel found in places like sweatpants waistbands, hoodie necklines, or sleeve cuffs. Its purpose is to hold elastic or a drawstring securely in place. The most common modern method for threading something through a casing involves attaching a safety pin to one end and pushing it through the narrow channel bit by bit. Anyone who has tried this knows how frustrating it can be. The pin often twists sideways, catches on seams, or worse, slips completely inside the casing, forcing the person to grope blindly through the fabric to find it again. What should be a quick task can easily turn into several minutes of annoyance.

The tiny hole was designed to eliminate this problem. It serves as a secondary anchor point. Instead of simply clipping the safety pin onto the end of the elastic or ribbon, the user adds one extra step: thread a thin piece of contrasting yarn, sturdy thread, or narrow cord through the small hole. Then, use the safety pin as usual to secure it to the drawstring or elastic.

By threading something through that small opening, the user gains far more control over the process. As the safety pin moves through the casing, the loose thread remains outside, held at the opening. This simple addition provides several important advantages:

It helps prevent twisting. Keeping light tension on the trailing thread encourages the safety pin to stay properly aligned, reducing the chance that it will flip sideways and snag inside the fabric.

It allows easy recovery. If the pin slips inside the casing or gets briefly stuck, the trailing thread acts like a lifeline. A gentle pull can reposition the pin or bring it back without cutting open seams or fumbling blindly.

It improves speed and accuracy. Instead of pushing and stopping repeatedly, the user can guide the pin smoothly, turning a tedious task into a faster, more controlled motion.

This small but brilliant design detail reflects the deep ingenuity found in classic, low-tech tools. It comes from a time when efficiency was built directly into objects themselves, allowing one tool to solve multiple problems without added parts or cost. For generations of tailors, seamstresses, and home repairers, this technique was simply common knowledge, passed down through experience rather than instruction manuals.

The importance of the safety pin’s hole goes beyond threading elastic. It highlights a broader principle behind traditional craftsmanship: every feature exists for a reason. Before modern, single-purpose tools became common, designers were expected to make each element of an object work as effectively as possible. This mindset can be seen in many historic sewing tools, such as the wide, flat head of tailor’s pins designed to withstand ironing, the angled tip of a seam ripper made for precision, or the heavy weight of antique sewing machines that ensured stability and consistent tension.

Applying this old wisdom today doesn’t mean rejecting modern tools. It simply means using what we already have more intelligently. By understanding and using the purpose of the safety pin’s tiny hole, modern users can save time, reduce frustration, and get better results. It perfectly illustrates the idea that the smartest solutions are often the simplest ones, quietly built into everyday objects.

Invented in 1849 by Walter Hunt, the safety pin has remained largely unchanged because its design struck an exceptional balance between safety, simplicity, and usefulness. That small hole, a silent witness to countless repairs and adjustments over the years, stands as a subtle reminder of that lasting brilliance. It shows us that true optimization doesn’t always come from complex technology or expensive gadgets, but from thoughtful design aimed at solving real human problems. All it takes is a moment to slow down, really look at the tool in your hand, and understand why it was made the way it was.